Reimagining the Three Little Pigs

When I say “natural building,” what comes to mind?

Most often I hear responses like, a hippie house, a mud hut, a Hobbit house, an Earthship, “Is that something like adobe?”, or the little pig’s straw house from the fairy tale. Some people love these associations and feel inspired to live in homes that look and feel hand built, as if they rose out of the landscape with the materials of that place. Yet, some who are drawn to this ethic of using natural, non-toxic, low carbon materials may be under the mistaken impression that building this way is impossible where they live. I get these associations and assumptions, but there are some naturally built homes and renovations that seamlessly weave themselves into the fabric of common American housing types and neighborhoods. They live as undercover natural homes.

I appreciate when homeowners, designers, and builders expand our imaginations of what is possible and create precedents for how natural building can be integrated into more residential building practices.

Jenna Yu is all of these—homeowner, designer, and builder using natural building techniques and materials. And when I learned of her natural built addition on her 1800 historic home in Providence, Rhode Island, I had to reach out to learn more.

In late January, my Rhode Island based Latitude colleague, Jeff Matteis, and I got to sit down at the kitchen counter with Jenna, so we could experience her space in person and get to know more about her story and her home.

Jenna is a humble, largely under the radar, revolutionary designer. (I just met her, and I think she may blush at that characterization, but I say it with admiration. It feels true from what I felt being in her home.) After years of organizing and holding straw bale building workshops on the West Coast with CASBA (California Straw Bale Association), she returned to Rhode Island and was able to apply her talents to her own homestead in the heart of Providence.

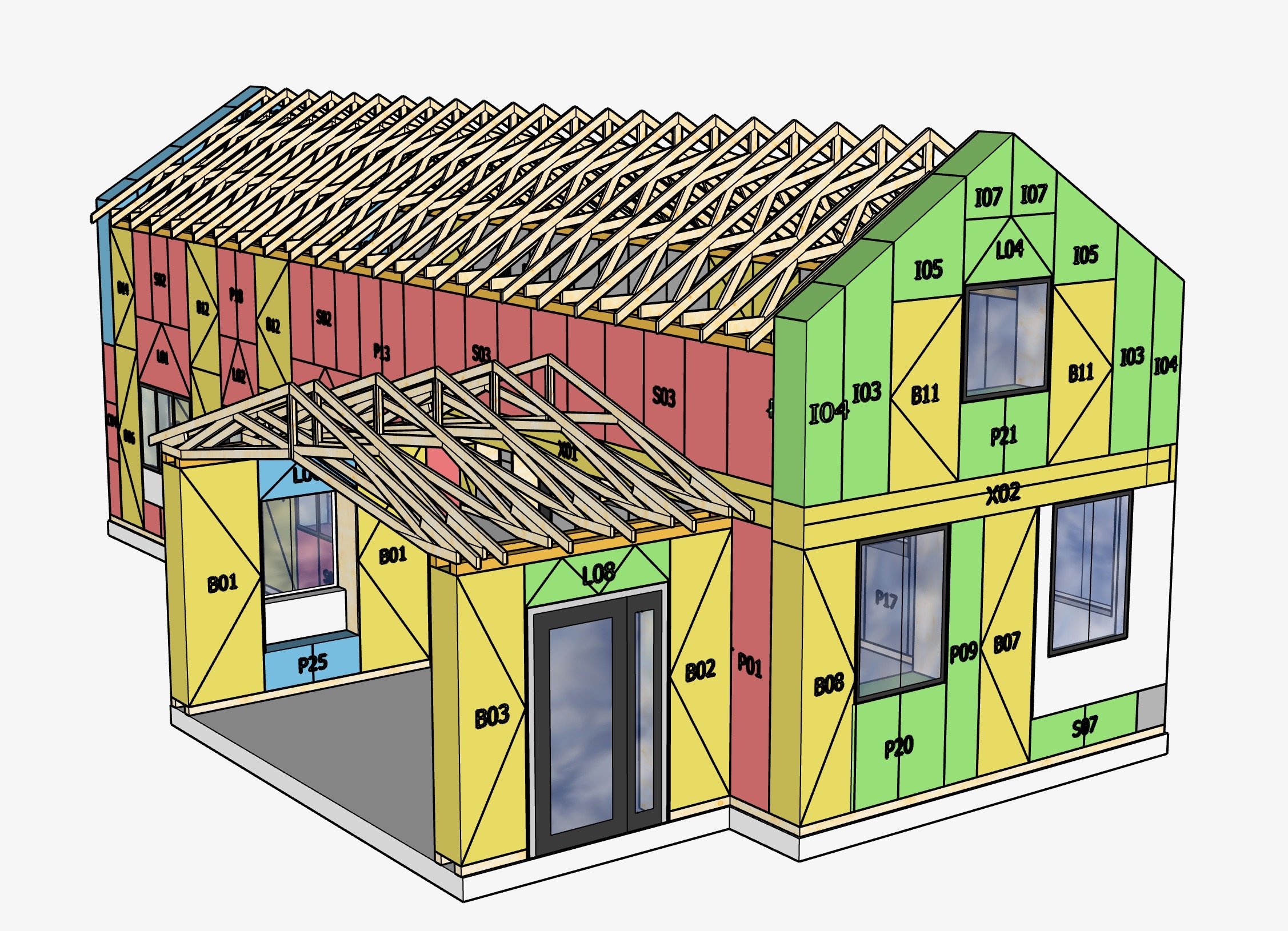

Jenna’s home is not constructed of straw bales like you might imagine from the Three Little Pigs or something you’ve seen in Sunset magazine. She used a structural straw panel system manufactured by Ecococon. (I learned about Jenna’s project from my Hudson Valley builder friend, Peter Jensen, who is the North American representative and expert on Ecococon’s building system. More to share about Peter another time…) The interior is finished with beautiful, hand-troweled clay plasters. The exterior mimics the lap siding of the adjoining 1800 home.

From the street, you’d never know this home is made of straw.

Jenna’s home sits as one of the early homes on the block among other homes from the 1800s and early 1900s. And since this building system arrives onsite as fully assembled panels that screw together in a couple of days, the home went up so fast that many neighbors probably never even saw the straw walls before they were enclosed in their weather barrier. Not that there is anything to hide, this type of panelized building just goes up that fast.

This story could end here.

The photos can speak for themselves to share a sense of the space, the materials used, and the context in which it is set. The images can help us reimagine and expand our sense of what natural building can look like and where it belongs.

But what else is significant about this type of project?

A lot…

Building with straw, and its kindred materials like hemp, is revolutionary. These compressed straw structural panels provide amazing insulation value, fire resistance, great sound attenuation, and integrate well with conventional building trades, if a homeowner wants to use conventional materials like sheet rock and common siding treatments. These qualities make for a beautiful, healthy, comfortable, and distinctly quiet home. These homes feel healing amidst the noise and disruption of modern life—a balm for our buzzing nervous systems.

Building with materials like straw creates the potential for a symbiotic relationship with local agricultural communities. Instead of bringing in wood from hundreds and thousands of miles away by ship, train, and truck, straw building can create locally available, rapidly renewable material supply chain that benefits local and regional agricultural industries.

There is more to tell, and great efforts are underway for lifting up the marketplace for locally sourced, rapidly renewable biomaterials like straw and hemp. While Ecococon is a European provider, we do have domestic options like Croft and New Frameworks. And, if current efforts succeed, we’re likely to see more regional manufacturing of products like these.

If regenerative agricultural practices could be deployed to create a reliable regional source of these materials, we’d have some key pieces for advanced carbon sequestration that goes beyond reduction in emissions. It could create a virtuous cycle of the more we build this way, the more carbon we can draw down out of the atmosphere—sinking carbon on the farming side of the supply chain and replacing high carbon materials with carbon sequestering materials on the building side.

If you’d like to connect about how natural materials could be integrated into your project, community, or development, please reach out.

Latitude’s aim is to create greater imagination and capability for regeneratively designed and inhabited spaces and places.

We’re here to create and be part of projects that strengthen community, are ecologically restorative, and celebrate the spirit of place.